Why Choose IP69K Hygienic Enclosures?

IP69K Hygienic Electrical Enclosures: Technical Design for Sanitary, Harsh and Hazardous Environments

In regulated industries, electrical and control systems must operate in environments where microbiological safety, regulatory compliance, and equipment uptime are equally critical. In these applications, conventional enclosures when designed for general industrial use often fail to meet hygienic design criteria.

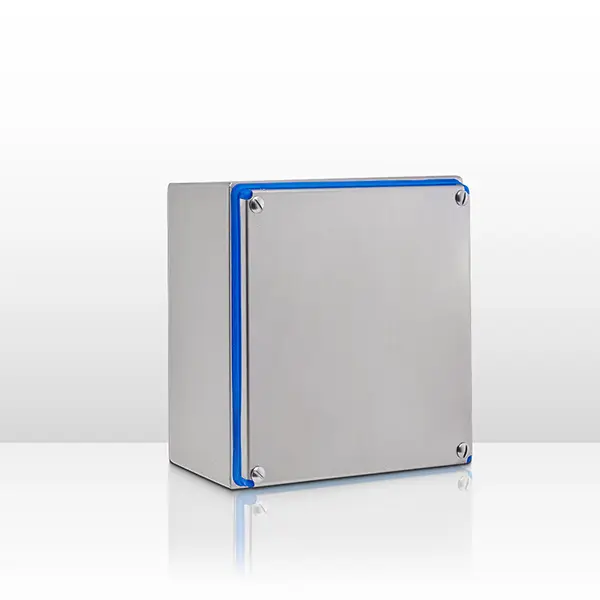

IP Enclosures’ IP69K Hygienic Electrical Enclosures, Terminal Boxes, and Pushbutton Enclosures are engineered in accordance with EHEDG (European Hygienic Engineering & Design Group) guidelines, tested to IP66 and IP69K ingress protection standards, and built to eliminate contamination risks while enduring decades of high-intensity cleaning cycles. The engineering rationale, technical specifications, validation testing, and industry applications for the IP69K Hygienic range are explained below.

The Hygienic Design Challenge

Hygiene as a Regulatory Imperative

In food processing, pharmaceuticals, biotechnology, and cleanroom manufacturing, enclosure failures can lead to contamination events that result in:

- Product recalls and brand damage.

- Regulatory non-compliance with HACCP, FDA 21 CFR Part 110/117, EHEDG, or EU Regulation (EC) No 1935/2004.

- Increased downtime for cleaning, repair, or equipment replacement.

Inherent Weak Points in Conventional Enclosures

Industrial enclosures designed without hygienic principles typically include:

- Horizontal ledges that retain standing water post-cleaning.

- Complex surface geometries with crevices that trap residues.

- Gasket materials that degrade under caustic, acidic, or chlorinated cleaning agents.

- Surface finishes exceeding Ra 0.8 µm, promoting biofilm formation.

- Ingress protection insufficient for high-pressure, high-temperature washdowns.

Design Philosophy: EHEDG-Compliant Engineering

IP Enclosures applies hygienic design methodology from the initial concept phase, ensuring that every component from base material selection to fastening systems, supports the primary objectives:

- Prevent Product Contamination

- Fully welded, monoblock construction eliminates joints where contaminants could lodge.

- 30° sloping roof geometry ensures self-drainage in accordance with EHEDG recommendations.

- Facilitate Cleaning Validation

- Blue FDA compliant silicone seals provide visual contrast for inspection and verification.

- Withstand CIP/SIP Cleaning Regimes

- Designed for exposure to high-pressure cleaning (80–100 bar), high-temperature water jets (80 °C), and aggressive detergents, acids, and alkalis.

- Maintain Mechanical Integrity Under Washdown

- Locking systems maintain uniform gasket compression to prevent micro-ingress.

- Stainless steel construction resists chloride-induced pitting corrosion.

- Support Hazardous Zone Compliance

- Optional IECEx certification ensures suitability in ATEX Zones 1, 2, 21, 22 for explosive dust or gas environments.

Material Science & Surface Engineering

Stainless Steel Selection

- Standard: Grade 304L stainless steel for general food and pharma environments.

- Optional: Grade 316L stainless steel for chloride-rich areas such as seafood processing or brine environments.

Surface Finish

- Brushed finish ≤ Ra 0.2 µm, in compliance with EHEDG Doc. 8 and ASME BPE criteria for cleanability.

- Minimises bacterial adhesion and facilitates surface sterilisation.

Gasket Engineering

- Material: FDA-compliant, silicone.

- Chemical Resistance: Stable against NaOH (1–5 %), HNO₃ (1–2 %), hypochlorite, peracetic acid, and steam.

- Thermal Performance: Operational range -60 °C to +200 °C.

Validation Testing

Ingress Protection Testing

- IP66: Protection against dust ingress and strong water jets (IEC 60529).

- IP69K: Per ISO 20653, enclosure subjected to high-pressure spray at 80–100 bar, 80 °C, from four angles at 0.25 m distance.

Mechanical Impact Testing

- IK07 / IK08 per IEC 62262: Ensures resistance to accidental impacts in industrial environments.

Compliance & Certification

- DGUV EN1672-2: Hygienic equipment design.

- IEC/EN 62208: Empty enclosure construction requirements.

- IECEx: Hazardous area suitability (optional).

- RoHS, CE, UKCA: Environmental and safety compliance.

Lifecycle Value

Total Cost of Ownership (TCO) Reduction

- 20+ year design life in compliant environments.

- Lower maintenance and cleaning time through optimised hygienic geometry.

- Reduced risk of contamination-related downtime.

Regulatory Confidence

- Fully aligned with EHEDG, DGUV, ISO, EN, IEC standards.

- Food contact safety assured through FDA and EC1935-compliant seals.

Industry Applications

Food & Beverage Processing

Application Environments:

- Dairy (pasteurisation, filling, packaging lines)

- Meat & poultry (cutting, deboning, packing)

- Bakery & confectionery (mixing, enrobing, cooling)

- Beverage (processing, bottling, canning)

Key Requirements:

- Frequent hot-water washdowns with alkaline detergents.

- Elimination of microbiological harbourage points.

- Resistance to sugar syrups, fats, and protein residues.

Solution: IP69K Hygienic enclosures with smooth, crevice-free design and self-draining roofs, ensuring rapid cleaning without compromising seal integrity.

Pharmaceutical & Biotechnology

Application Environments:

- Solid dose (tablet presses, coating lines)

- Liquid fill (aseptic filling, vial capping)

- Laboratory environments (BSL-2 / BSL-3 facilities)

Key Requirements:

- Particle-free surface finish to prevent contamination.

- Chemical resistance to alcohols, peracetic acid, hydrogen peroxide vapour (HPV).

- Compatibility with cleanroom classification up to ISO 5.

Solution: Monoblock construction with brushed Ra ≤ 0.2 µm stainless steel, FDA gaskets.

Chemical Processing & Hazardous Areas

Application Environments:

- Chemical mixing rooms

- Spray drying facilities

- Solvent handling zones

- Powder transfer lines

Key Requirements:

- Chemical-resistant materials and gaskets.

- Protection from corrosive vapours and dust.

- Compliance with IECEx/ATEX requirements for explosive atmospheres.

Solution: Optional Grade 316L construction with IECEx certification, ensuring safe operation in both corrosive and hazardous settings.

Hygienic Enclosures, Pushbutton Enclosures & Terminal Boxes

Choose IP69K Hygienic electrical enclosures, pushbutton enclosures and terminal boxes.

IP Enclosures’ IP69K Hygienic range represents the convergence of hygienic design principles, advanced materials engineering, and industrial-grade construction. For industries operating at the intersection of stringent hygiene requirements and demanding environmental conditions, these enclosures provide a validated, durable, and regulation-compliant solution that supports both operational efficiency and public safety.

IP69K Hygienic Electrical Enclosures

304 Stainless Steel

Up to IP69K

IP69K Pushbutton Enclosures

304 Stainless Steel

Up to IP69K

IP69K Terminal Boxes

304 Stainless Steel

Up to IP69K