Powder Coating of Enclosures: Durable, UV-Protected, Customisable

At IP Enclosures, we offer a comprehensive range of powder coated electrical enclosures with a colour range tailored to meet your specific requirements. Our enclosures are powder coated to 80-120 micron average thickness using AkzoNobel’s Interpon range, renowned for their exceptional durability and aesthetic appeal. Whether you need standard colours or custom RAL shades, our enclosures provide both functional protection and a professional finish.

The powder coating process involves applying a dry powder that is then cured under heat, forming a tough, uniform layer. This method ensures superior adhesion and resistance to environmental factors. AkzoNobel’s Interpon coatings are formulated to withstand UV radiation, preventing colour fading and surface degradation over time. This UV stability is crucial for maintaining the integrity and appearance of enclosures exposed to harsh sunlight.

In addition to their UV resistance, Interpon coatings offer excellent corrosion protection, making them ideal for both indoor and outdoor applications. The coatings are also eco-friendly, containing no solvents or emission of minimal volatile organic compounds (VOCs), aligning with sustainable practices. With a wide selection of colours and finishes, IP Enclosures ensures that your electrical enclosures not only provide protection in the harshest conditions, but also enhance the visual appeal of your installations.

Beyond durability, our coloured enclosures are designed with aesthetics in mind. Consultants, Architects, Councils, and Planners can select finishes that blend seamlessly into natural or urban environments, ensuring functional equipment does not disrupt visual harmony. In addition to our standard range of colours, we can provide custom colours from subtle earth tones to modern metallic finishes to support projects where both performance and appearance are equally important.

Proper care of IP Enclosures’ powder-coated steel electrical enclosures ensures long-term corrosion resistance, appearance, and performance. Clean the surface regularly based on environment. Annually for indoor units, and every 3-6 months for outdoor or harsh industrial locations using mild pH-neutral detergent, warm water, and soft cloths or sponges, while avoiding harsh solvents, abrasives, or high-pressure sprays. Remove stains such as bird droppings, grease, or embedded rust promptly, and repair any chips or scratches with a zinc-rich primer and colour-matched touch-up paint. In coastal or chemically aggressive environments, periodic rinsing and protective coatings help maintain the finish, ensuring the powder coating continues to provide reliable protection and a professional appearance throughout the enclosure’s 20-year design life.

Light Grey

Jet Black

T33

Smoke Blue

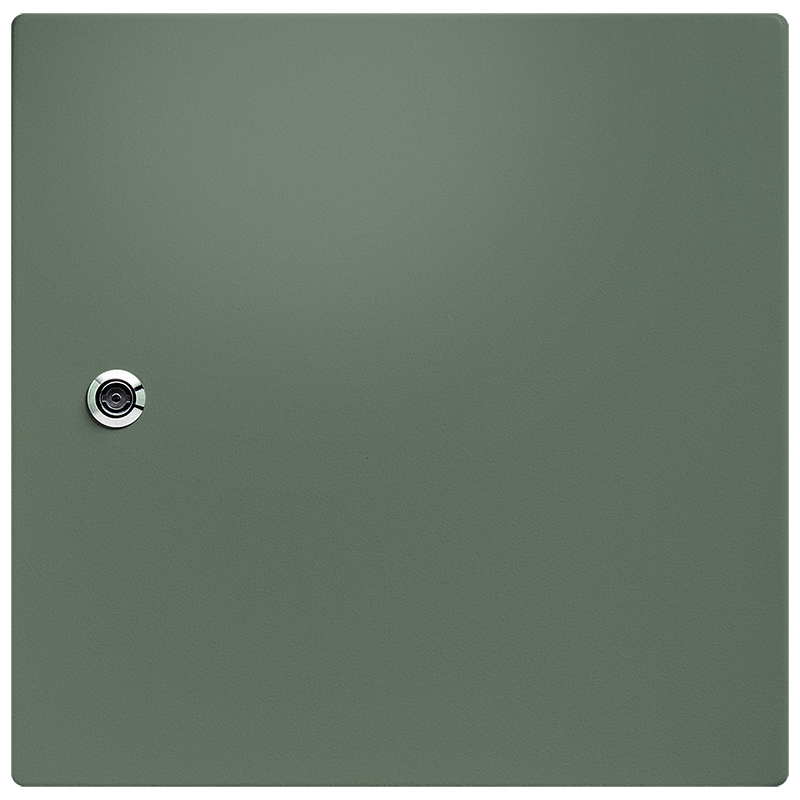

Wilderness

Green

X15

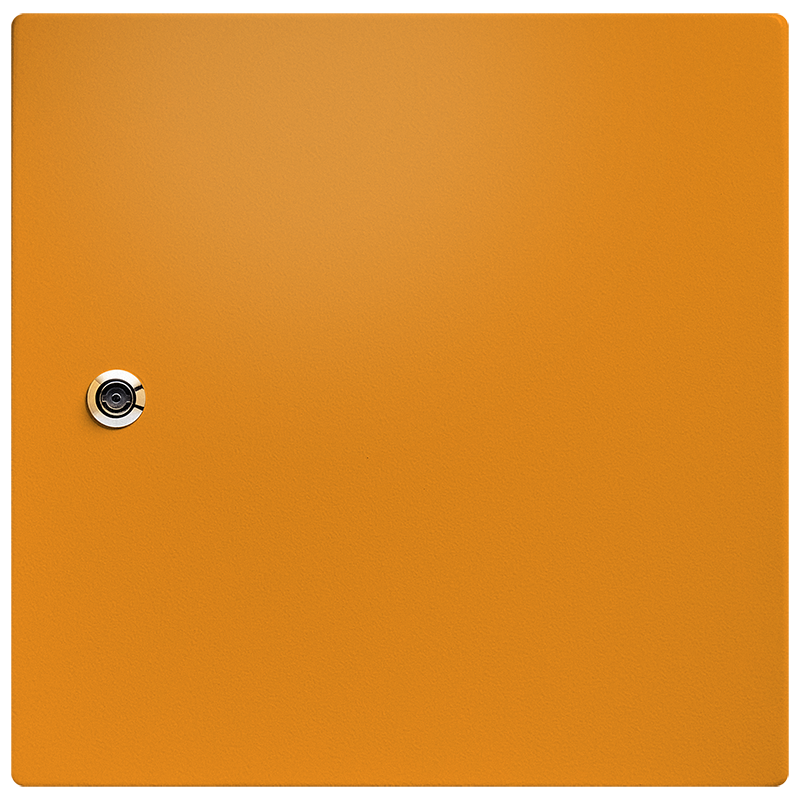

Orange

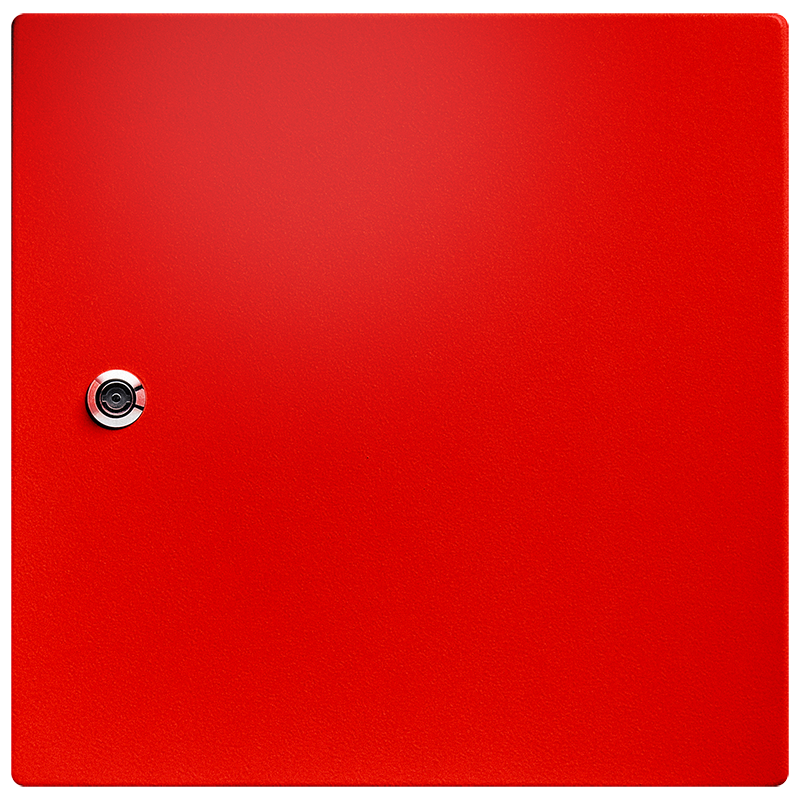

R13

Signal Red